How Do Air Brakes Work on a Tractor Trailer?

Tractor-trailer rigs utilize compressed air, not hydraulics, for braking. This system offers both immense stopping power and enhanced safety features. Let's explore the key components and their functions.

For more on air brake issues, see this helpful resource.

The Air Supply: Generating and Storing Compressed Air

The air compressor, the heart of the system, continuously pumps air into a network of air lines. This compressed air is stored in large tanks, acting as a reserve supply. These tanks ensure sufficient braking power even if the compressor malfunctions briefly. Maintaining adequate air pressure (typically 90-120 PSI) is crucial; low pressure triggers warning lights and significantly diminishes braking effectiveness. Regular pressure checks are paramount. Do you regularly check your air pressure gauges?

Distributing the Stopping Power: Air Lines and Valves

A sophisticated network of air lines and valves distributes compressed air to each wheel. The service brake valve, connected to your brake pedal, controls the release and application of the brakes. Depressing the pedal releases compressed air to the brake chambers. Relay valves then carefully regulate air flow to the trailer brakes, achieving even braking across the entire rig. This coordinated system is essential for smooth, controlled stops.

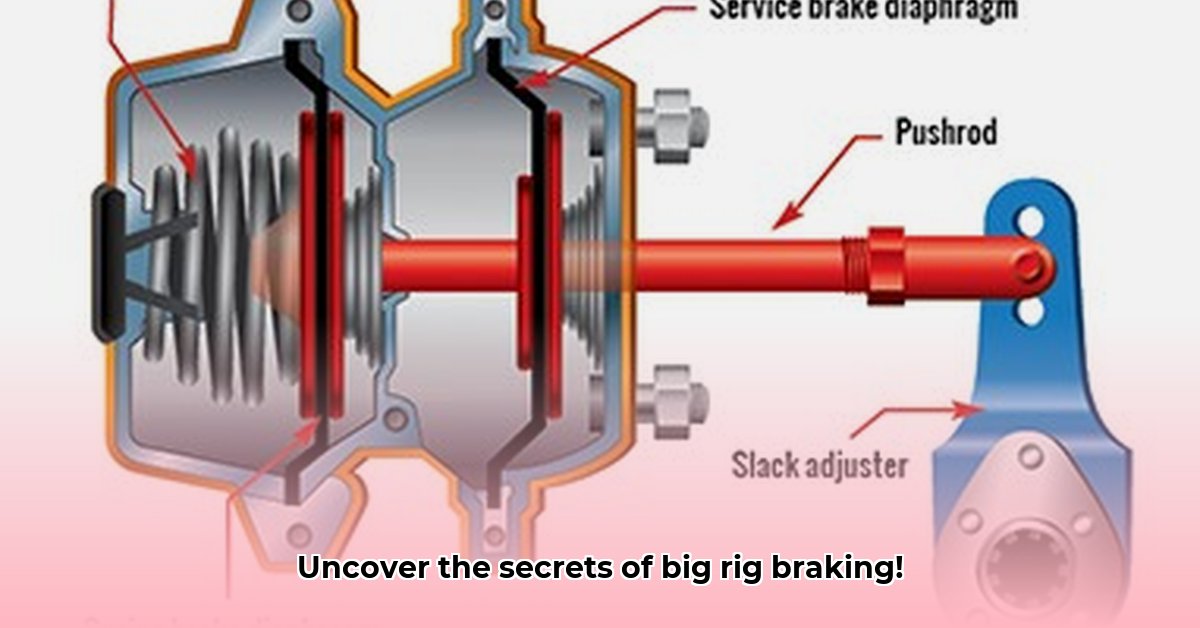

Transforming Air Pressure into Stopping Power: Brake Chambers and Actuators

Compressed air reaches brake chambers at each wheel. These chambers contain diaphragms or pistons. Increased air pressure pushes these components, mechanically activating the brakes. Two main types exist: S-cam (drum brakes) and diaphragm (disc brakes). Both convert air pressure into the physical force needed to slow or stop the wheels.

Types of Air Brakes: Drum vs. Disc

Drum Brakes (S-cam): Employ a cam mechanism within a drum to press brake shoes against the rotating drum. They are generally simpler and cheaper to maintain but less effective in wet conditions and prone to "brake fade" (reduced braking performance after extended use).

Disc Brakes: Utilize calipers that clamp brake pads against a rotating disc, offering superior stopping power, particularly in adverse weather, and longer lifespans. Modern trucks often use a combination of both types.

| Brake Type | Pros | Cons |

|---|---|---|

| Drum (S-cam) | Simpler, lower initial cost | Less effective in wet conditions, prone to fade |

| Disc | Superior stopping power, longer lifespan | Higher initial cost, more complex design |

Emergency Brakes: Spring Brakes as Fail-Safes

A key safety feature is the spring brake system. If major air line failure or a significant leak occurs, these brakes automatically engage, ensuring a controlled stop. They represent a crucial emergency backup system.

How to Optimize Tractor-Trailer Air Brake Maintenance for Maximum Lifespan

Regular maintenance is paramount. Leaks, worn components, and low air pressure severely compromise safety and regulatory compliance. Consistent inspections and prompt repairs are vital. Did you know that proactive maintenance can reduce downtime by up to 75%? 1

Regular Inspections: A Proactive Approach

Regular inspections are essential. Check:

- Air Pressure: Maintain correct air pressure; low pressure indicates leaks or compressor issues.

- Air Leaks: Listen for hissing near valves, lines, and chambers.

- Brake Pedal Feel: A spongy pedal suggests air leaks or other problems. A firm pedal ensures braking confidence.

- Visual Inspection: Regularly examine brake lines, air hoses, and chambers for damage or wear.

- Slack Adjusters: Ensure these automatic brake shoe clearance adjusters function correctly and are properly adjusted.

Daily pre-trip inspections are crucial; more thorough professional checks should occur at specified mileage intervals.

Proactive Component Replacement: Predictive Maintenance

Even with regular inspections, components wear out. Predictive maintenance is key to extending system lifespan.

- Brake Shoes/Pads: Replace according to manufacturer recommendations based on mileage and driving conditions.

- Air Hoses and Lines: Replace at the first sign of cracks, kinks, or abrasions.

- Air Compressor: Regular oil changes and maintenance extend its lifespan.

- Other Components: Valves and other parts have their own service intervals. Refer to your owner's manual.

Replacing components proactively prevents costly breakdowns and ensures reliable braking.

Maintaining Detailed Maintenance Records

Keep comprehensive maintenance logs, tracking repairs, replacements, and inspection findings. This facilitates better decision-making, identifies trends, and helps with preventative maintenance. It's also important for regulatory compliance.

Driver Training: Essential for System Longevity

Proper driver training on safe braking techniques minimizes component wear. Aggressive braking puts excessive stress on the air brake system. Periodic refresher courses reinforce safe practices.

The Economic Benefits of Preventative Maintenance

While preventative maintenance requires upfront investment, it's significantly more cost-effective than catastrophic brake failure, which can lead to costly repairs, downtime, potential accidents, and liability claims.